If you are considering automating your product packaging, the biggest challenge will be to decide exactly what you want, and what will work best for your product. Gone are the days when you have to accept run-of-the-mill packaging; instead Technik’s custom solutions will accommodate just about anything you need.

Customizable solutions from Technik include cost-effective, automated pick and place as well as transfer systems, sleeving and tray and lid packers. You are bound to find the perfect product packing solution here.

Tray and Lid Packers

Ideal for products that need to be sealed and stacked in trays ready for retail stores, Dienst HE TL Tray and Lid Packers offer a fully automated solution. The way it works is that trays are formed from corrugated blanks before products are inserted into each tray. Trays are then sealed using either hot- or cold-melt glue and any required coding or labeling is applied to completed trays.

Ideal for products that need to be sealed and stacked in trays ready for retail stores, Dienst HE TL Tray and Lid Packers offer a fully automated solution. The way it works is that trays are formed from corrugated blanks before products are inserted into each tray. Trays are then sealed using either hot- or cold-melt glue and any required coding or labeling is applied to completed trays.

Trays that can be assembled range in size from 105 mm to 600 mm in length; 70 mm to 400 mm in width; and 70 mm to 400 mm in height. All drive axes are controlled by servos, and 25 trays can be packed in just one minute.

These tray and lid packing machines weigh 2,000 kg, and they are suitable for a wide range of products including dry, fresh, liquid and frozen items, and household foodstuffs including coffee, candy, condiments, pasta and rice. They are also suitable for industrial and pharmaceutical products, as well as cosmetics and nutraceuticals.

Automated Sleeving Systems

Technik also supplies fully automated Dienst automated sleeving systems that are ideal for trays and various other retail products that require wraparound paperboard sleeves.

Technik also supplies fully automated Dienst automated sleeving systems that are ideal for trays and various other retail products that require wraparound paperboard sleeves.

The Dienst HS II S is a reliable, high performance machine that weighs in at 1,750 kg. A very cost-effective option, it produces and wraps up to 200 sleeves every minute. The way it works is that products are fed into the machine where they are wrapped by the sleeve that is then sealed with hot-melt glue. If required, sleeves can also be affixed directly to products with glue.

This sleeving system, which can be remote controlled, is perfect for a number of industry applications including dry, fresh and frozen foodstuffs, pasta, candy and snack foods, and pet foods, as well as cosmetics, pharmaceutical and nutraceutical products, and industrial items.

The second option is the Dienst HS IV S that is the same weight as the HS II S and offers the same performance of 200 sleeves per minute. It is also suitable for the same applications.

Transfer Systems

Technik has a variety of transfer systems available for products that have to be collated and synchronized, sorted, stacked and fed into automated packaging equipment, including automated sleeving systems and tray and lid packers.

While transfer systems are customized for client requirements, they are all based on common components to make them cost effective. Engineers are available to help build the right transfer system for each application.

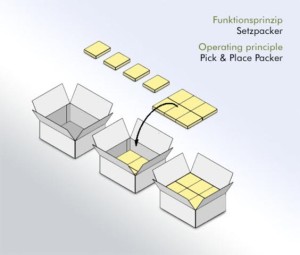

Pick and Place Systems

Pick and place systems are available for products that have to be collated and then top-loaded into various containers. Technik offers various Dienst systems that are flexible but cost-effective, and, like the transfer systems they offer, are based on common components. These systems use vacuum or gripper plate pick-up options that are so varied they will meet the requirements of most products. Tray erecting and closing can be done manually or the pick and place system may be used in conjunction with other Dienst automated equipment.

Pick and place systems are available for products that have to be collated and then top-loaded into various containers. Technik offers various Dienst systems that are flexible but cost-effective, and, like the transfer systems they offer, are based on common components. These systems use vacuum or gripper plate pick-up options that are so varied they will meet the requirements of most products. Tray erecting and closing can be done manually or the pick and place system may be used in conjunction with other Dienst automated equipment.

As for transfer systems, pick and place options are customized and Technik Packaging Machinery engineers will ensure that every system meets the clients packaging needs.

So if you’re looking for reliable, cost-effective equipment that will enable you to automate the packaging process for you products, contact us today.

Follow Us!